Real and Fake in a 3D Printed World

Table of Contents

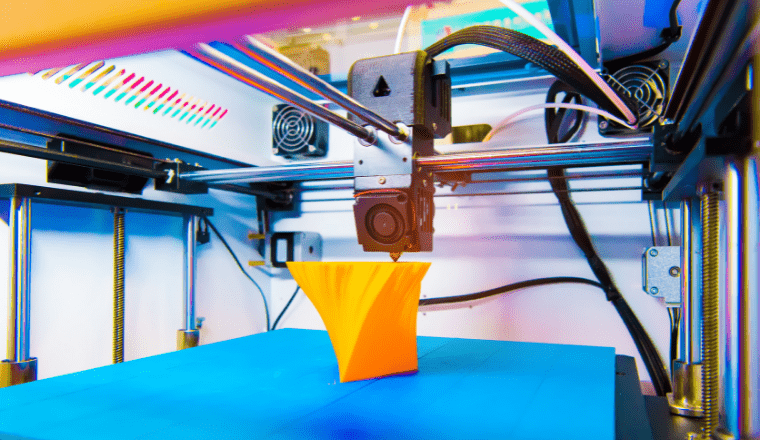

There is an allure to magic; watching a magician wave a wand and seemingly create something out of nothing. Well, such is the appeal of a 3D printer, for there is nothing in front of you at first, then it moves and it seems to render layer upon layer until finally the lines take form and you recognize the final product. In some cases, the 3D rendering is so accurate it is almost impossible to distinguish the real from the fake. Thus creating a copyright web that is often impossible to untangle. In a 3D printed world, is it possible for creators to protect their intellectual property rights from counterfeiters? In this article, we take a look at what is real and fake in a 3D printed world and the implications of 3D printing on Intellectual Property.

What is 3D Printing?

3D printing is an umbrella term for various rapid, quick, and cheap prototyping, replication, or fabrication technologies that emerged in the late 1980s. They build products or parts using a layer-by-layer fashion with several methods emerging for printing plastic and metal products. In addition, the 3D printing methods vary in the ways they layer different materials, their surface finish, durability, speed, and cost.

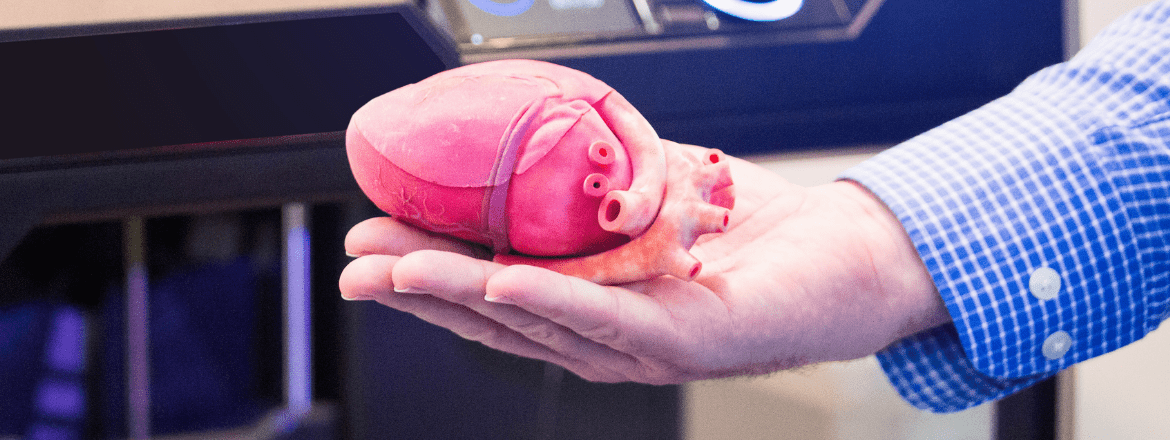

In fact, 3D printing is a form of additive manufacturing, a method of creating three-dimensional objects, ranging from small silicon parts to entire footbridges, from a digital file. An additive process creates objects through successive layers of material with each layer representing a thin slice of the final object's cross-section. 3D printing has the advantage of producing complex objects using less material compared to traditional manufacturing methods.

Traditionally, most products are made in a subtractive manner, with large amounts of raw materials carved into small parts that are then joined together. Subtractive manufacturing often leads to excessive waste and by-products, a problem additive manufacturing eliminates. Thus thanks to 3D printing, manufacturing is now cheaper and more efficient than ever.

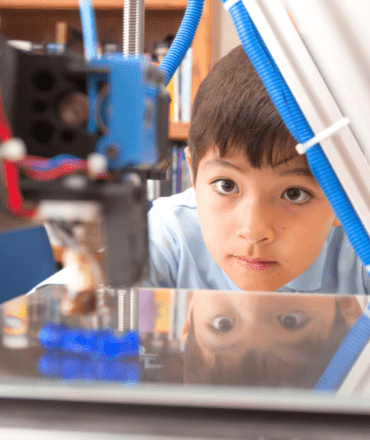

However, with 3D printers no longer costing millions of dollars and with production profits going into billions, 3D printers have entered people’s homes and there are fears that IP rights are being infringed upon. Notably, cheaper models cost less than a thousand dollars. For such a price bracket, the printers are mostly basic plastic extruding machines limited to printing basic plastic components. The cheaper the model, the more it is prone to mistakes and the more unsophisticated its renderings are.

The convergence of 3D printing and 3D visualization using AR is making waves among homeowners who want to revamp their living spaces. This technology allows them to craft bespoke items that cater to their individual tastes and requirements. What's more, they can also envision potential home improvements with remarkable clarity and make informed choices even before any actual work commences. As an added bonus, the detailed models generated by 3D printing and AR can guide DIY projects, as well as serve as an educational resource. This innovation is poised to change the way we live in our homes, bringing about a whole new level of comfort and customization.

Counterfeits cause crashes, fires, and injuries, and 3D printing can turn anyone into a credible manufacturer

How 3D Printing Works

First, 3D printing requires a 3D digital scan either designed by the printer or derived from a digital library. Secondly, the printer requires 3D software which ranges from industrial grade to open source. In fact, beginner-friendly 3D software like Tinkercard is free and can be easily run from any computer. This ease of use and access is one of the reasons why 3D printing is helping to fuel the black market of counterfeit products. Making it harder for authorities to enforce intellectual property rights. In addition to the 3D software, the printer requires 'slicing software' which turns the 3D model into hundreds or thousands of slices or layers. For instance, 3D printed medical devices were used at the start of the Covid-19 crisis in 2020.

3D Printing and Intellectual Property

3D printing technology is currently not easy for non-experts. The process is tedious and time-consuming. The chances of the public stockpiling raw materials ready for use at home are also highly unlikely. Even with these limitations, home-based operators still have a vast selection of blueprints that they can render at their disposal.

While blueprints are subject to IP protection, infringement can occur anywhere making it difficult for the law to intervene on time. Even then, IP rights are territorial in nature, meaning that IP rights only grant power over acts done in their granting jurisdiction. As such, rendering parts and assembling them into a patented machine, in the United States, is only an infringement if there is an American patent. There is no global body to enforce IP rights. However, talks are almost complete in the EU for a unitary patent system where a single court can capture infringement across all member countries.

3D Printers as a Tool for Counterfeiting

Counterfeit products are astronomically inferior to the real thing. The problem is that an unsuspecting new customer may be fleeced for not knowing the difference. When the fake product underperforms, the blame is heaped on the original brand. As opposed to fake fashion and cell phone accessories, a greater threat is in fake mass-produced goods such as fake bolts, screws, linings, and fittings. These products are used in building homes, offices, cars, and schools and such fake 3D printed products will not adhere to the strict quality requirements, tensile strength, or even standards required for durability.

As a result, such low-quality components, after being confused with their genuine counterparts, have caused aviation and traffic accidents. When strict sourcing regulations are flouted, lives may be lost. Many attempts at thwarting 3D printed fake goods have proven difficult to implement. Many third-world countries, for example, still lack proper testing, inspection, and conformity programs to verify the authenticity of products imported into their borders.

So far, the most promising verification method is a technique by InfraTrac, which adds a chemical solution to anything without altering any of its chemical composition. In this way, a fingerprint component treated with the chemical may be hidden under the surface of the product to serve as an authentication method. InfraTrac and other firms have proven that 3D tech can be used for anti-counterfeiting by the use of watermarks. Their CEO Sharon Flank also states,

“Counterfeits cause crashes, fires, and injuries, and 3D printing can turn anyone into a credible manufacturer."

There are also wide-scale fears of 3D printers printing cash and guns. Another promising company Applied DNA Sciences, uses molecular-based protection, with plant DNA marking original goods. They authenticate supply chains, mark cash in transit, live copper cables, fish, and entire neighborhoods. And of course, there is no evidence that their ink can be produced by 3D printers.

Fighting 3D Copyright Infringement

However, luxury brand Salvatore Ferragamo began embedding radio frequency identification (RFID) chips into some of its products including shoes, bags, and luggage. But, this has failed to snuff out the production of counterfeits.

Therefore, as the fight to regulate counterfeit products grows it is increasingly important for designers and creators to patent, trademark, and copyright their products. Based on the Berne Convention, creators are automatically granted intellectual property protection for their creations. While this is indeed helpful, it is often hard to enforce such a claim if it is not formerly registered.

Conclusion

3D printing infringement can be realized on two fronts. The first infringement is through the copying of the digital twin or design used. Copying a product only requires an electronic schematic of the product and a 3D printer. As such, any object can be easily reproduced based on its digital design or a 3D scan. The second infringement is realized in the physical copy of the printed product.

The global counterfeit industry was worth over $500 billion in 2016 and has grown year on year since then. In addition, the European Union’s Office for Harmonization in the Internal Market (OHIM) issued a report stating that about 10% of fashion products sold globally are counterfeits amounting to about $28.5 billion in lost revenue annually in Europe alone.

While 3D printing clearly has some manufacturing benefits, there is a need for better regulation of products and authenticity certification. Unfortunately, that process will take a while, especially for different countries to harmonize their regulatory and certification processes. In the meantime, designers, manufacturers, and other creators need to take measures to protect and enforce their IP rights.

For more information and guidance on intellectual property protection, please contact us at [email protected]